our products are selling well in the American, European, South American and Asian markets. a specialized supplier of a full range of chains, sprockets, gears, gear racks, V-belts, couplings and reducers, pto shaft, agricultural gearboxes….

Overview

Quick Details

-

Applicable Industries:

-

Manufacturing Plant

-

Brand Name:

-

OEM

-

ITEM NO:

-

SYF

-

Product Keywords:

-

WP worm speed reducer

-

Application:

-

Transmission equipment

-

Color:

-

Customer Requirement

-

Material:

-

Cast Iron

-

Ratio:

-

5-100

-

Certificate:

-

ISO9001

-

Mounting Position:

-

Horizontal (foot Mounted)

-

Bearing:

PTO Shaft A PTO Adapter will be useful when operating Victory’s EMSD and EMHD Embankment Flail mowers. The absence of a PTO Adapter could cause the PTO shaft to conflict with the arm weldment, which connects to the CAT I/II 3 point hitch.

-

NSK

-

Warranty:

-

1 Year

Packaging & Delivery

-

Lead Time

:

-

| Quantity(Pieces) |

1 – 100 |

>100 |

| Est. Time(days) |

15 |

To be negotiated |

Online Customization

Product Description

WP series worm gear reducer

WP reducer, divided into standard WPS series, standard WPD series, standard WPA, WPO,WPDA,WPDO,WPDS,WPDS and so on. WP worm gear and worm gearbox is developed on the basis of WD reducer, the worm is made of 45 # high quality steel after heat treatment processing and manufacturing, worm gear with tin bronze cast, wear-resisting performance is good, especially on the bearing capacity is more obvious, worm gear and worm gearbox is mainly used in plastics, metallurgy, beverage, mining, lifting transport, chemical reduction drive construction and other mechanical equipment.

Advantages

1.Smooth transmission, vibration, impact and noise are small, speed reduction ratio, wide versatility, can be used with a variety of mechanical equipment.

2.Can be a single level of transmission to obtain a larger transmission ratio, compact structure, most models of reducer has a good self-locking, braking requirements of mechanical equipment can save the braking device

3.worm tooth tooth meshing friction loss is large, so the transmission efficiency is lower than the gear, easy to heat and high temperature.

4.Higher requirements for lubrication and cooling.

5.Good mutual compatibility, worm gear and worm are manufactured according to national standards, bearings, oil seals and other standard parts.

6.The box body type includes basic type (the box body is vertical or horizontal type with foot board) and universal type (the box body is cuboid, with fixed screw holes on multiple sides, without foot board or another foot board, etc.).

7. There are two connection modes of input shaft: basic type (single input shaft and double input shaft) and motor flange.

8. The position direction of the output and input axes is below and above the input axes; Output shaft up and down; Input axis up and down.

9. Two or three reducer sets can be used to form a multistage reducer to obtain a maximum transmission ratio.

More options for worm gear reducers

Single speed reducer

Ratio1/10-1/60

Universal speed reducer

Ratio1/10-1/60

Double speed reducer

Ratio1/100-1/3600

Our Company

HangZhouEver Power Electromechanical Equipment Supply Station

We handle the products of power transmission, our lines mainly cover series products in speed reducers, gearboxes , associated electricial motors and other power transmission accessories. Based on the versatile functions, our products can be utilized in many fields: machines of waste water treatment, dredgers, chemical industry, cranes, metal working mills, conveyors, paper industry, cement industry, cableways and so on.With the excellent quality and reasonable price , our products enjoy a good reputation from customers and the peers all over the world.

Furthermore, the R&D investment are annually increasing for the purpose of better meeting the new demands of our customers and adapting the new tendency of the industry.

Depending on the principles of honestly operating and mutual benefit, We sincerely look forward to cooperating with you.

Main products of the company:

|

NMRV worm gearbox

|

Cycloidal speed reducer

|

R/S/K/F gear motor

|

JZQ soft tooth gearbox

|

|

|

|

|

|

|

Hard tooth gearbox

|

WP series worm gearbox

|

AC induction motor

|

Electrical drum pulley

|

|

|

|

|

|

Company goals:

Our goal is to make customers experience the best products with the best service.

To get five-star praise ★★★★★

Application area

Large gear reducer used in steel works

Planetary reducer is used in mining industry

Reducer and electric roller are used together

Gear reducer for mixing equipment

Cycloidal reducer for mixing equipment

Cycloidal reducer is used in chemical reaction kettle

Reducer industry application:

Reducer products are widely used in metallurgical mines, oil, electric power, chemical rubber, construction, building materials machinery, railway vehicle, port shipping, textile printing and dyeing, food packaging, tobacco, pharmaceutical, environmental protection, paper making, printing, lifting transport, logistics, loading and unloading, animal husbandry, fishery, forestry machinery, light industry, leather, casting, welding, refrigeration and other general equipment and stage, game consoles, cableway, three-dimensional garage and other non-standard equipment.

More Technical Presentation of Our Products Adhering to “Survival by Quality, Development by Technology & Credit”, The company will constantly improve product performance to meet the increasing customer requirements in the rigorous style of work.

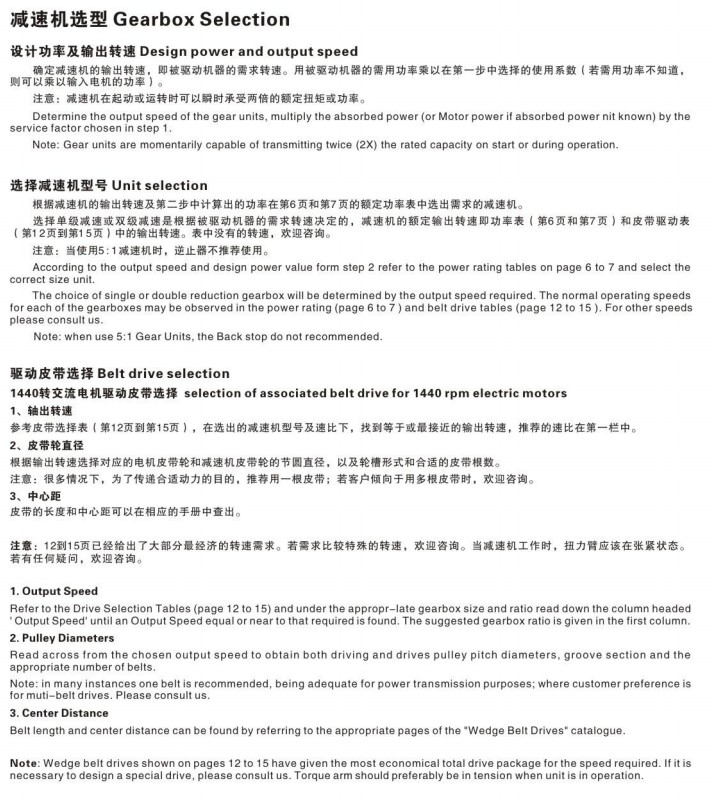

Materials:cast iron gear case, worm shaft is of Alloy Steel, duly hardened and tempered. The worm wheel is made of Chill Cast Phosphorous Bronze. Fabrication Crafts:liberal ribbing for increasing heat dissipation area, streamlined sump for carrying more oil and fan of ample size which is effective in both side of rotation. Design Standards:We practically apply American,EU,Japan or Indian Design standards .Worm Shafts conform to case- hardening Alloy Steels, Worm Wheels conform to phosphorous-bronze as per BS 1400, While Gear case conforms to C.I. Grade 20, IS210. Other exclusive features :Worm & Worm Wheels: The worm is made of case-hardening / alloy steel, duly hardened, ground and lapped and is integral with the shaft. Bearing journals ate accurately ground. Worm Wheels is made of chill cast phosphorous bronze and tightSeries B Right Angle Worm GearEPG Drive Series B Right Angle Worm Gearly fitted with the C.I. Centres. Worm Wheels teeth are generated on precision hobbing machines and high accuracy hobs. Adaptable Worm Gearbox Bearings: The Worm and Worm Wheels are supported on Extra Heavy Duty Tappet roller anti friction bearings of ample margin of safety to allow adequate journals as well as thrust loads. Overhung loads arising Out of sprocket or pinion drive are generally permissible because the gear case and bearing are designed for this duty. In case of heavy overhung load, and extra roller bearing can be provided. Wheel Shafts: The Worm wheel Shafts are made of high tensile carbon steel, duly hardened and ground. It is of large diameter of carry the torsional as well as the bending loads which may be induced by overhung drives. Lubrication: Lubrication in Worm gearbox is by splash of oil from the sump. Thus, no special care is required except for the occasional oil topping of the oil to the required level. An oil filler cum breather plug is provided along with the drain plug and level plug. Oil seals of appropriate size are provided on all input and output shafts.Only For very low input speed of below 50 RPM, and heavy loads in sizes above 350 mm, forced lubrication is required. Worm Gearbox Cooling: Air cooling is effected by means of standard propylene or metal fans which direct air over the ribbed surface of the Case. The fan is designed to operate in both the direction of rotation and is so arranged in conjunction with the ribbing of the case to allow maximum heat dissipation. Overload Ratings: All the Components of the Gear Unit are so designed that they can withstand 100% overload for 15 seconds 50% overload for one minute 40% overload for 15 minutes 25% overload for 1 hour How to choose a proper type of Gearbox :It is recommended that as much as possible of the following information be given in the enquiry or order so that a check can be made and advice given on the most suitable size of Worm Speed Reducer for any application.1.Type of prime mover.2. Horse-power of prime mover.3. Output torque required from driven member. 4. Input speed of gear unit.5. Output speed of gear unit. 6. Configuration of drive required and shaft disposition. 7. Total daily hours of running. If running is intermitteTo get the type-choose reference,please contact our technical rep or sales rep .

Packing&Transportion

Characteristics of transportation and packaging

● Short delivery period,to ensure timely delivery.

● Tight packing,to ensure the products are not damaged during transportation.

● Various modes of transportation,to ensure safe and timely transportation.

● Follow up the whole process of order,to ensure product delivery to customers.

● Long shelf life, to ensure customer experience.

|

Mode of transportation

|

Weight Range

|

Transportation Time

|

Advantage

|

Disadvantage

|

|

Express Delivery

|

Below 50kg

|

Around a week

|

Short lead time,

Door-to-door

Delivery

|

High Express Cost

|

|

Air Transportation

|

30kg-150kg

|

Around a week

|

Short lead time

|

High Express Cost,

Customer pick-up

|

|

Sea Transportation

|

Over 150kg

|

15-20 days

|

Low cost

|

Long transport time

|

|

Railway Transportation

|

Over 100kg

|

15-20 days

|

Inland transport

|

Affected by geography

|

FAQ

Q1: Are you a trading company or a manufacturer ?

A: We are a manufacturer in ZheJiang Province, China. Our company owns the ability of manufacturing, processing, designing and R&D. We welcome your visit.

Q2: How we select models and specifications?

A: According to the specific details of the demands from the part of enquiry, we will recommend the products’ models upon synthesizing the factors of field of products usage, power, torque arm and ratio…

Q3: How is your price? Can you offer any discount?

A: Our prices are always competitive. If the customer can place a large order, we surely will allow discount.

Q4: How long should I wait for the feedback after I send the enquiry?

A: We will reply the enquiries without any delay, 12 hours at most.

Q5: What is your product warranty period?

A: We have the certifications of ISO99001,CE,

Q6: What industries are your gearboxes being used?

A: Our gearboxes are widely applied to metallurgical equipment, mining equipment, automation equipment, food machinery, packaging equipment, tobacco equipment and so on.