EPG will always adhere to it enterprise spirit of being practical, innovative, efficient and excellent to make the top international transmission drive.

Overview

Quick Details

-

Applicable Industries:

-

Hotels, Garment Shops, Building Material Shops, Manufacturing Plant, Machinery Repair Shops, Food & Beverage Factory, farms, Energy & Mining, Construction works

-

Place of Origin:Zhejiang, China

-

Brand Name:

-

OEM

-

Gearing Arrangement:

-

Helical

Slip Clutch PTO Shaft for Compact Tractor Tillers NEW SLIPCLUTCH PTO SHAFT FOR COMPACT TRACTOR TILLERS ROTO TILLERS BUSHHOG RHINO KINGKUTTER,CARONI,MASCHIO,JOHN DEERE, MOST MODELS three different types of PTO in operation: a non shear, shear pin and slip clutch — the last being the most expensive. Implement end of non shear (r) and shear type (l) Non shear: this is a solid yoke to yoke set up and used with the expectation that certain equipment will not encounter any sudden stops. I figure that the finishing mower does not need a shear set up as the blades will slip to a degree being belt driven and my other mower, the flail mower, is extremely forgiving in its design.

-

Output Torque:

-

10~62800N.m

-

Input Speed:

-

1450/960rpm

-

Output Speed:

-

14-280rpm

-

Ratio:

-

5.36~197.37

-

Certification:

-

ISO9001-2008

-

Mount Position:

-

Our factory has obtained the certificate of China’s Farm Machinery Products Quality Authentication promulgated by the Farm Machinery Products Quality Authentication Centre of China.

Foot Mounted

-

Bearing:

-

LYC, HRB,ZWZ,NSK

To address these sealing and efficiency issues, Emerson Power Transmission (EPT) developed several design and manufacturing recommendations. The resulting gearboxes tend to run cooler and leak free, compared with conventional worm gear units.

Supply Ability

-

Supply Ability:

- 500 Unit/Units per Month

Packaging & Delivery

- Packaging Details

- Wooden boxes , Cantons packed in 1 pallet

- Port

- Ningbo Port, Shanghai Port

Online Customization

K series 90 degree hollow shaft bevel helical gear electric motor speed reducer reverse gear box for motorcycle

Product Description

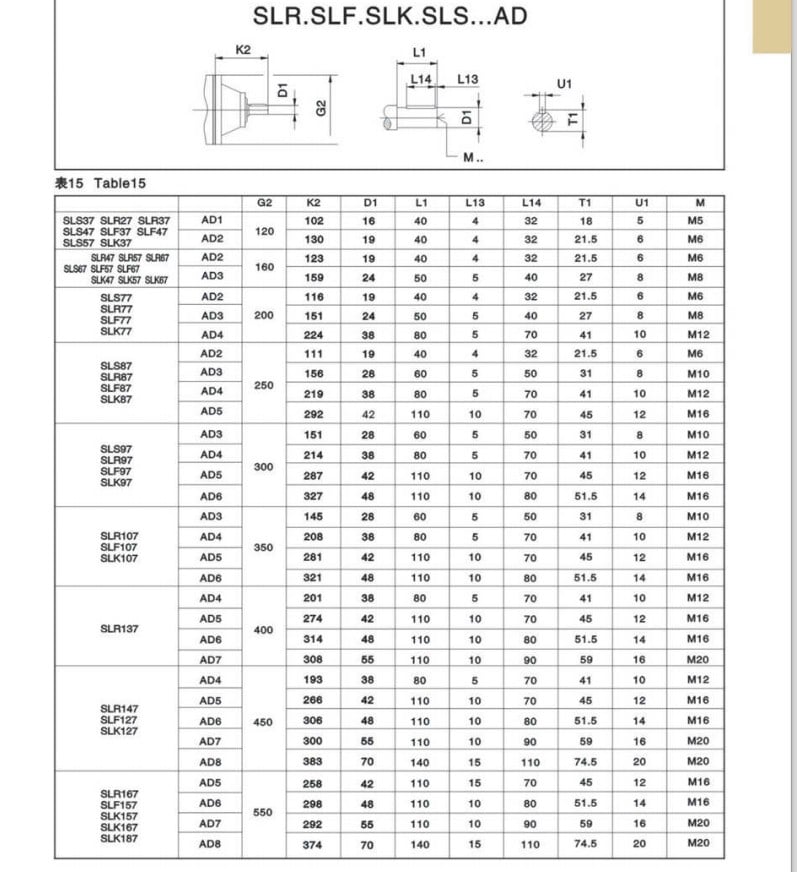

SLK series gearbox is one kind of Helical Bevel type gearbox , High-stainless cast iron case . ,it is designed based on modularization , which bring many difference kinds of combinations ,mounting types ,and structure designs .The detail classification of ratio can meet various of working condition .High Transmission efficiency ,Low energy consumption, superior performance . The hard tooth surface gear use the high quality alloy steel , the process of carburizing and quenching, grinding ,which give it follow characters : Stable transmission , low noise and temperature ,high loading ,long working life. which widely use for industry equipment of metallurgy ,Building Material , Chemical , Mining , Oil, Transportation , Papermaking , Sugar making , engineering Machines ,etc

Specifications:

1) Output speed: 0.6~1,028r/min

2) Output torque: up to 21700N.m

3) Motor power: 0.12~200kW

4) Mounted form: foot-mounted and flange-mounted mounting

|

Product Name

|

SLK Series Rigid Tooth helical bevel reducer

|

|

Gear Material

|

20CrMnTi

|

|

Case Material

|

HT250

|

|

Shaft Material

|

20CrMnTi

|

|

Gear Processing

|

Grinding finish by HOFLER Grinding Machines

|

|

Color

|

Customized

|

|

Noise Test

|

65~70dB

|

|

Efficiency

|

94%~98% (depends on the transmission stage)

|

|

Lubricating oil

|

Shell Omala synthetic oil or mineral oil , or similar brand

|

|

Heat treatment

|

tempering, cementiting, quenching,etc.

|

|

Brand of bearings

|

C&U bearing, ZWZ,LYC, HRB, SKF,NSK and so on

|

|

Brand of oil seal

|

NAK or other brand

|

|

Temp. rise (MAX)

|

40 °

|

|

title

|

helical motor bevel geared,sew gear motor

|

|

Temp. rise (Oil)(MAX)

|

50 °

|

|

Vibration

|

≤20µm

|

Company Information

Certifications

Our Services

Packaging & Shipping

Related Products

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us