We – EPG Group the largest worm gearbox, couplings and gears manufacturing facility in China with 5 diverse branches. For far more particulars: Mobile/whatsapp/telegram/Kakao us at: 0086~13083988828 13858117778083988828 /

OEM Manafacturer F Sequence Parallel Shaft Helical Gearbox

Factors:

one. Housing: Forged Iron

two. Gears: Hardened Helical Gears

three. Enter Configurations:

Outfitted with Electric powered Motors

Solid Shaft Enter

IEC-normalized Motor Flange

4. Relevant Motors:

One Stage AC Motor, 3 Period AC Motor

Brake Motors

Inverter Motors

Multi-speed Motors

Explosion-proof Motor

Roller Motor

5. Output Configurations:

Strong Shaft Output

Hollow Shaft Output

Designs:

F Series – Foot-mounted, reliable shaft output

FAB Sequence – Foot-mounted, hollow shaft output

FA Sequence – Keyed hollow shaft output

FF Sequence – B5 Flange-mounted, reliable shaft output

FAF Sequence – B5 Flange-mounted, hollow shaft output

FAZ Sequence – B14 Flange-mounted, hollow shaft output

Body fat Series – Hollow shaft output, torque arm

FH, FHB, FHF, FHZ Collection – Hollow shaft output, shrink disk

FV, FVB, FVF, FVZ Sequence – Hollow shaft output, splined hollow shaft

F(FA, FF, FAF, FAB, FAZ)S Collection – Solid shaft input

Attributes:

one. Modular design and style, compact composition. Additional-slender parallel shaft helical gearmotors are the best remedy when space is minimal

2. F sequence parallel shaft helical gearmotors are typically utilised in conveyors and supplies processing apps

three. Multi-phase(2 or 3 levels) gear units for low output speed

four. Hollow output shaft with keyed relationship, shrink disk, splined hollow shaft, or torque arm

5. Can be blended with other varieties of gearboxes (These kinds of as R Sequence, UDL Sequence)

6. Optional mounting possibilities (foot-mounted, flange-mounted, shaft-mounted)

Parameters:

| Versions | Output Shaft Dia. | Input Shaft Dia. | Power(kW) | Ratio | Max. Torque(Nm) | |

| Sound Shaft | Hollow Shaft | |||||

| F38 | 25mm | 30mm | 16mm | .18~3. | three.81~128.51 | two hundred |

| F48 | 30mm | 35mm | 16mm | .eighteen~3. | five.06~189.39 | 400 |

| F58 | 35mm | 40mm | 19mm | .eighteen~5.5 | 5.18~199.70 | 600 |

| F68 | 40mm | 40mm | 19mm | .18~5.five | 4.21~228.99 | 820 |

| F78 | 50mm | 50mm | 24mm | .37~11 | 4.30~281.seventy one | 1500 |

| F88 | 60mm | 60mm | 28mm | .seventy five~22 | 4.20~271.92 | 3000 |

| F98 | 70mm | 70mm | 38mm | one.1~30 | four.68~276.64 | 4300 |

| F108 | 90mm | 90mm | 42mm | two.2~forty five | 6.20~255.twenty five | 7840 |

| F128 | 110mm | 100mm | 55mm | seven.5~ninety | four.sixty three~172.33 | 12000 |

| F158 | 120mm | 120mm | 70mm | eleven~two hundred | twelve.07~270.18 | 18000 |

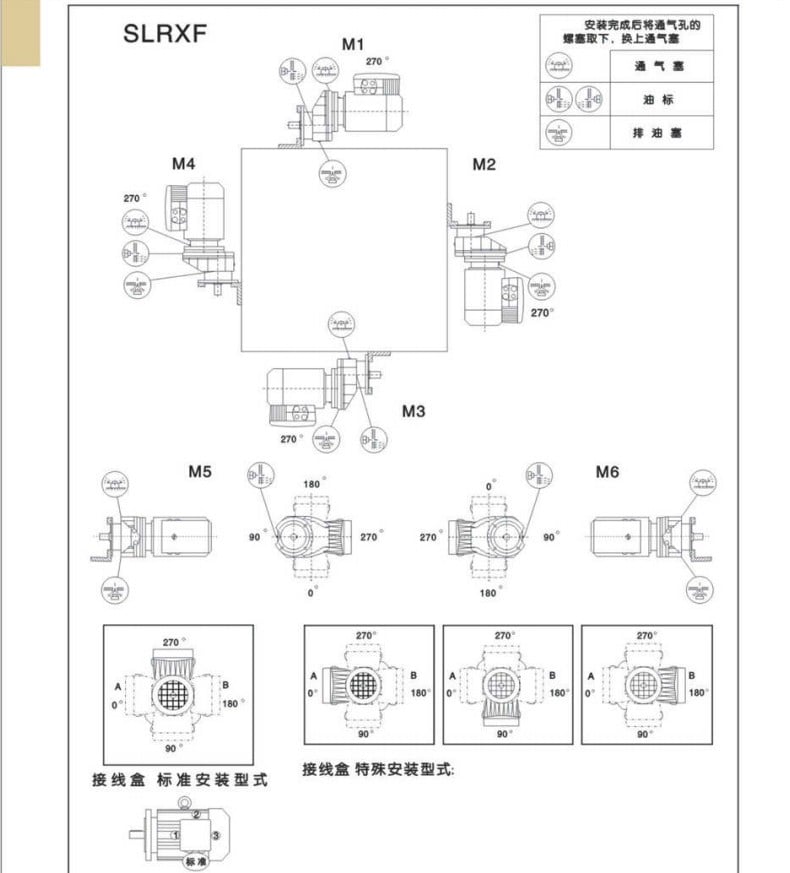

Set up:

Foot-mounted

B5 Flange-mounted

B14 Flange-mounted

Shaft-mounted

Lubrication:

Oil-tub and Splash Lubrication

Cooling:

Natural Cooling

Product pictures

Product application:

Pac ept & Delivery:

Our business :

AOKMAN® was started in 1982, which has a lot more than 36 years in R & D and producing of gearboxes, gears, shaft, motor and spare areas.

We can provide the suitable answer for uncountable apps. Our goods are broadly utilised in the ranges of metallurgical, metal, mining, pulp and paper, sugar and alcohol market place and numerous other types of equipment with a sturdy existence in the intercontinental marketplace.

AOKMAN® has grow to be a trustworthy provider, in a position to source large top quality gearboxes.With 36 many years experience, we guarantee you the utmost trustworthiness and security for the two product and providers.

Buyer checking out:

Our Providers:

| Pre-sale providers | 1. Pick equipment model. |

| 2.Layout and manufacture merchandise according to clients’ specific requirement. | |

| 3.Teach technical personal for customers | |

| Services in the course of marketing | 1.Pre-check and settle for merchandise ahead of supply. |

| two. Support consumers to draft solving strategies. | |

| After-sale services | one.Support clientele to prepare for the 1st construction scheme. |

| 2. Prepare the initial-line operators. | |

| 3.Take initiative to eradicate the trouble swiftly. | |

| four. Give specialized exchanging. |

FAQ:

If you have specific parameters and necessity for our gearbox, customization is obtainable.

/ The use of authentic equipment manufacturer’s (OEM) element quantities or emblems , e.g. CASE® and John Deere® are for reference reasons only and for indicating item use and compatibility. Our firm and the outlined replacement parts contained herein are not sponsored, accredited, or made by the OEM. /