Product Description

Drive shafts gear spline shaft with oem machining carbon steel/brass/bronze or stainless steel

Feature of CNC parts

1. Precision Cnc stainless steel parts strictly according to customer’s drawing,packing and quality request

2. Tolerance: Can be kept in +/-0.005mm

3. The most advanced CMM inspector to ensure the quality

4. Experienced technology engineers and well trained workers

5. Fast and timely delivery. Speedily&professional service

6. Give customer professional suggestion while in the process of customer designing to save costs.Our freight price is often 30-50% lower than customer’s

7. Customers can use PAYPAL and other online payment platform to pay a small amount of sample fee to shorten the sample production time

8. Quality assurance in accordance with ISO9001:2015 and ISO13485:2016

Material Available for CNC Machining

| Material | Stainless steel | SS201 SS303 SS304 SS316 17-4PH SUS440C |

| Steel | Q235 20#-45# etc | |

| Brass | C36000(C26800) C37700(HPb59) C38500(HP6 58) C27200(CuzN37)etc | |

| Iron | 1213 12L14 1215 etc | |

| Bronze | C51000 C52100 C5400etc | |

| Aluminum | Al6061 Al6063 Al7075 AL5052 etc | |

| Alloy | A2 D2 SKD11 DF2 XW/5 ASP-23 |

Terms and Conditons

| Our Processing | CNC machining, CNC milling and turning, drilling, grinding, , stamping, tapping, |

| Surface finish | Hard Coating Black Anodize Clear Anodize Hard Chrome ,Clear Zinc Plasma Niride |

| Tolerance | 0.005mm |

| QC System | 100% inspection before shipment |

| Drawing format | DWG/ IGS/ STEP/STEP,/IGES/X-T/PDF and etc. |

| Packaging | Standard package / Carton box or Pallet / As per customized specifications |

| Payment Terms | 1) Western Union for samples cost or very small order 2) 100% T/T in advance when amount less than 1000USD 3) 50% deposit, 50% balance by T/T before shipment when order amount from 3000USD to 5000USD. 4) 30% deposit, 70% balance by T/T before shipment when order amount over 5000USD. 5) L/C payment term for big amount order is acceptable. |

| Trade terms | EXW, FOB, CIF, As per customer’s request |

| Shipment Terms | 1) 0-100kg: express & air freight priority 2) >100kg: sea freight priority 3) As per customized specifications |

| Note |

All CNC machining parts are custom made according to customer’s drawings or samples, no stock.If you have any CNC machining parts to be made, please feel free to send your kind drawings/samples to us anytime by email. |

KGL Machinery&Electronics Co., Ltd.(KGL) was founded in 2013, an independent private enterprise that integrated R&D, production, sales and service.KGL is focused on CNC precision machining parts, mainly applied in the field of robotics, communications, medical, automation, and custom-designed complex parts and custom-designed equipment.The core competitiveness is rapid response capability, quality assurance system and cost control ability.We provide value-added services to customers through more technical supporting, high quality product and rapid response business processing.So customers will be more focused on their own business and thus enhance customer value.

KGL Machinery&Electronics Co., Ltd.Now has high precision 3 axis CNC vertical machining center, 4 axis machining center, 5 axis machining center imported from ZheJiang , precision grinding machine, precision wire-cut, EDM and CNC lathe about 50 units.The Max machining range is 2100*1600*800mm, and the machining accuracy can be achieved to 0.005mm.The inspection instrument has CMM, profile projector, digital micro dial, high gauge, ID &OD micrometer, and so on.Professional and experienced management, engineers, inspectors and production staff is about 80.The main processing materials include cast iron, extruded material, steel, aluminum alloy, copper, stainless steel and various engineering plastics.

Our company is aiming at “professional quality and CZPT service”.We have passed ISO9001:2015 and ISO13485:2016 quality management system certification.The company has always been oriented by customer demand and respect for talents, constantly improve their strength, improve service level and quality.With many European and American, Asian and domestic customers, we have established long-term good relationship with common progress.Sincerely expect to join hands with you to create the future.

ISO13485:2003 ISO9001:2008

Exhibition:

Q1:Are you a manufacturer?

A1:Yes, we are a medium size ISO13485/ISO9001 certificated manufacturer with a wide range of advanced equipment.Warmly welcome to visit our factory so that you can make sure this point.

Q2:What is the MOQ?

A2:Minimum Order Quantity is 1 piece/set.If you require more qty,the price can be more competitive.

Q3:Can you do the mass production?

A3:Yes,we are a factory which can provide service of precision CNC machining, rapid prototyping, wire cutting, tooling building and etc.After you confirm the samples, we can start mass production.It is very convienient for customers to

Choose us as a one-stop solution supplier.

Q4:Which 3D drawing files should go with the machines?

A4:CNC machines only read *IGS,*STP,*STEP,*IGES,*X-T format, for *STL format,it goes with 3D printer and SLA.

Q5:Is it possible to know how are my products going on without visiting your company?

A5:We will offer a detailed production schedule and send weekly reports with pictures or videos which show the machining progress.

Q6:Will my drawings be safe after sending to you?

A6:Yes, we will keep them well and not release to third party without your permission.

Q7:What shall we do if we do not have drawings?

A7:Please send your sample to our factory,then we can copy or provide you better solutions.Please send us pictures or drafts with dimensions(Length,Hight,Width),CAD or 3D file will be made for you if placed order.

Thank you very much for reading, and warmly welcome to inquiry or visit us.

If any question please feel free to contact.

| Material: | Carbon Steel |

|---|---|

| Load: | Central Spindle |

| Stiffness & Flexibility: | Stiffness / Rigid Axle |

| Journal Diameter Dimensional Accuracy: | IT6-IT9 |

| Axis Shape: | Gear Spline Shaft |

| Shaft Shape: | Stepped Shaft |

| Samples: |

US$ 200/Piece

1 Piece(Min.Order) | |

|---|

| Customization: |

Available

| Customized Request |

|---|

Driveshaft structure and vibrations associated with it

The structure of the drive shaft is critical to its efficiency and reliability. Drive shafts typically contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Learn about the different types of drive shafts and how they work. If you want to know the vibrations associated with them, read on. But first, let’s define what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the demand on our drive systems. Higher CO2 emission standards and stricter emission standards increase the stress on the drive system while improving comfort and shortening the turning radius. These and other negative effects can place significant stress and wear on components, which can lead to driveshaft failure and increase vehicle safety risks. Therefore, the drive shaft must be inspected and replaced regularly.

Depending on your model, you may only need to replace one driveshaft. However, the cost to replace both driveshafts ranges from $650 to $1850. Additionally, you may incur labor costs ranging from $140 to $250. The labor price will depend on your car model and its drivetrain type. In general, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into four major markets: North America, Europe, Asia Pacific, and Rest of the World. North America is expected to dominate the market, while Europe and Asia Pacific are expected to grow the fastest. Furthermore, the market is expected to grow at the highest rate in the future, driven by economic growth in the Asia Pacific region. Furthermore, most of the vehicles sold globally are produced in these regions.

The most important feature of the driveshaft is to transfer the power of the engine to useful work. Drive shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or both. Due to the complexity of driveshaft assemblies, they are critical to vehicle safety. In addition to transmitting torque from the engine, they must also compensate for deflection, angular changes and length changes.

type

Different types of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head provide a rotationally secure connection. At least one bearing has a groove extending along its circumferential length that allows the pin to pass through the bearing. There can also be two flanges on each end of the shaft. Depending on the application, the shaft can be installed in the most convenient location to function.

Propeller shafts are usually made of high-quality steel with high specific strength and modulus. However, they can also be made from advanced composite materials such as carbon fiber, Kevlar and fiberglass. Another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a high strength-to-weight ratio. Both drive shafts and screw shafts are used to drive cars, ships and motorcycles.

Sliding and tubular yokes are common components of drive shafts. By design, their angles must be equal or intersect to provide the correct angle of operation. Unless the working angles are equal, the shaft vibrates twice per revolution, causing torsional vibrations. The best way to avoid this is to make sure the two yokes are properly aligned. Crucially, these components have the same working angle to ensure smooth power flow.

The type of drive shaft varies according to the type of motor. Some are geared, while others are non-geared. In some cases, the drive shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to control the speed and direction of the drive. In some applications where linear power transmission is not possible, flexible shafts are a useful option. For example, flexible shafts can be used in portable devices.

put up

The construction of the drive shaft has many advantages over bare metal. A shaft that is flexible in multiple directions is easier to maintain than a shaft that is rigid in other directions. The shaft body and coupling flange can be made of different materials, and the flange can be made of a different material than the main shaft body. For example, the coupling flange can be made of steel. The main shaft body is preferably flared on at least one end, and the at least one coupling flange includes a first generally frustoconical projection extending into the flared end of the main shaft body.

The normal stiffness of fiber-based shafts is achieved by the orientation of parallel fibers along the length of the shaft. However, the bending stiffness of this shaft is reduced due to the change in fiber orientation. Since the fibers continue to travel in the same direction from the first end to the second end, the reinforcement that increases the torsional stiffness of the shaft is not affected. In contrast, a fiber-based shaft is also flexible because it uses ribs that are approximately 90 degrees from the centerline of the shaft.

In addition to the helical ribs, the drive shaft 100 may also contain reinforcing elements. These reinforcing elements maintain the structural integrity of the shaft. These reinforcing elements are called helical ribs. They have ribs on both the outer and inner surfaces. This is to prevent shaft breakage. These elements can also be shaped to be flexible enough to accommodate some of the forces generated by the drive. Shafts can be designed using these methods and made into worm-like drive shafts.

vibration

The most common cause of drive shaft vibration is improper installation. There are five common types of driveshaft vibration, each related to installation parameters. To prevent this from happening, you should understand what causes these vibrations and how to fix them. The most common types of vibration are listed below. This article describes some common drive shaft vibration solutions. It may also be beneficial to consider the advice of a professional vibration technician for drive shaft vibration control.

If you’re not sure if the problem is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should contact an expert as soon as possible. If vibration persists after vibration-related repairs, the driveshaft needs to be replaced. If the driveshaft is still under warranty, you can repair it yourself.

CV joints are the most common cause of third-order driveshaft vibration. If they are binding or fail, they need to be replaced. Alternatively, your CV joints may just be misaligned. If it is loose, you can check the CV connector. Another common cause of drive shaft vibration is improper assembly. Improper alignment of the yokes on both ends of the shaft can cause them to vibrate.

Incorrect trim height can also cause driveshaft vibration. Correct trim height is necessary to prevent drive shaft wobble. Whether your vehicle is new or old, you can perform some basic fixes to minimize problems. One of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Next, attach an ounce of weight to it and spin it. By doing this, you minimize the frequency of vibration.

cost

The global driveshaft market is expected to exceed (xxx) million USD by 2028, growing at a compound annual growth rate (CAGR) of XX%. Its soaring growth can be attributed to several factors, including increasing urbanization and R&D investments by leading market players. The report also includes an in-depth analysis of key market trends and their impact on the industry. Additionally, the report provides a comprehensive regional analysis of the Driveshaft Market.

The cost of replacing the drive shaft depends on the type of repair required and the cause of the failure. Typical repair costs range from $300 to $750. Rear-wheel drive cars usually cost more. But front-wheel drive vehicles cost less than four-wheel drive vehicles. You may also choose to try repairing the driveshaft yourself. However, it is important to do your research and make sure you have the necessary tools and equipment to perform the job properly.

The report also covers the competitive landscape of the Drive Shafts market. It includes graphical representations, detailed statistics, management policies, and governance components. Additionally, it includes a detailed cost analysis. Additionally, the report presents views on the COVID-19 market and future trends. The report also provides valuable information to help you decide how to compete in your industry. When you buy a report like this, you are adding credibility to your work.

A quality driveshaft can improve your game by ensuring distance from the tee and improving responsiveness. The new material in the shaft construction is lighter, stronger and more responsive than ever before, so it is becoming a key part of the driver. And there are a variety of options to suit any budget. The main factor to consider when buying a shaft is its quality. However, it’s important to note that quality doesn’t come cheap and you should always choose an axle based on what your budget can handle.

editor by CX 2023-07-13

China 191-2674 1912674 Sun Gear for E322C E324D E324E Planetary Gearbox drive shaft components

Situation: New, 1-, etc Truck Crane Partsmonitor screen display IK2, and so forth Packing & Delivery Company Data ZheJiang CZPT heavy sector co., LTD. (Tai ‘an) is a renowned supplier of design equipment parts in China. Our products truck crane, bulldozer, excavator, grader, excavator loader, roller and various construction equipment components, and so forth. FAQ Q1. Are you an authorized distributor? A: Indeed we are, China Manufacturing unit Provide Steel Track Excavator Undercarriage Spare Areas we are the sole agent.Q2. Exactly where are you positioned? A: We are located in CZPT town, getting our possess components warehouse, and technological servicing personnel for machine. Q3. Do you sell Legitimate items or else? A: We supply only manufacturer new genuine spare parts or goods and we DO NOT market re-manufacture or employed types. Q4. What if the areas ended up broken or broken? A: We will resend another new 1 to you.

How to Identify a Faulty Drive Shaft

The most common problems associated with automotive driveshafts include clicking and rubbing noises. While driving, the noise from the driver’s seat is often noticeable. An experienced auto mechanic can easily identify whether the sound is coming from both sides or from one side. If you notice any of these signs, it’s time to send your car in for a proper diagnosis. Here’s a guide to determining if your car’s driveshaft is faulty:

Symptoms of Driveshaft Failure

If you’re having trouble turning your car, it’s time to check your vehicle’s driveshaft. A bad driveshaft can limit the overall control of your car, and you should fix it as soon as possible to avoid further problems. Other symptoms of a propshaft failure include strange noises from under the vehicle and difficulty shifting gears. Squeaking from under the vehicle is another sign of a faulty driveshaft.

If your driveshaft fails, your car will stop. Although the engine will still run, the wheels will not turn. You may hear strange noises from under the vehicle, but this is a rare symptom of a propshaft failure. However, you will have plenty of time to fix the problem. If you don’t hear any noise, the problem is not affecting your vehicle’s ability to move.

The most obvious signs of a driveshaft failure are dull sounds, squeaks or vibrations. If the drive shaft is unbalanced, it is likely to damage the transmission. It will require a trailer to remove it from your vehicle. Apart from that, it can also affect your car’s performance and require repairs. So if you hear these signs in your car, be sure to have it checked by a mechanic right away.

Drive shaft assembly

When designing a propshaft, the design should be based on the torque required to drive the vehicle. When this torque is too high, it can cause irreversible failure of the drive shaft. Therefore, a good drive shaft design should have a long service life. Here are some tips to help you design a good driveshaft. Some of the main components of the driveshaft are listed below.

Snap Ring: The snap ring is a removable part that secures the bearing cup assembly in the yoke cross hole. It also has a groove for locating the snap ring. Spline: A spline is a patented tubular machined element with a series of ridges that fit into the grooves of the mating piece. The bearing cup assembly consists of a shaft and end fittings.

U-joint: U-joint is required due to the angular displacement between the T-shaped housing and the pinion. This angle is especially large in raised 4x4s. The design of the U-joint must guarantee a constant rotational speed. Proper driveshaft design must account for the difference in angular velocity between the shafts. The T-bracket and output shaft are attached to the bearing caps at both ends.

U-joint

Your vehicle has a set of U-joints on the driveshaft. If your vehicle needs to be replaced, you can do it yourself. You will need a hammer, ratchet and socket. In order to remove the U-joint, you must first remove the bearing cup. In some cases you will need to use a hammer to remove the bearing cup, you should be careful as you don’t want to damage the drive shaft. If you cannot remove the bearing cup, you can also use a vise to press it out.

There are two types of U-joints. One is held by a yoke and the other is held by a c-clamp. A full ring is safer and ideal for vehicles that are often used off-road. In some cases, a full circle can be used to repair a c-clamp u-joint.

In addition to excessive torque, extreme loads and improper lubrication are common causes of U-joint failure. The U-joint on the driveshaft can also be damaged if the engine is modified. If you are driving a vehicle with a heavily modified engine, it is not enough to replace the OE U-joint. In this case, it is important to take the time to properly lubricate these components as needed to keep them functional.

tube yoke

QU40866 Tube Yoke is a common replacement for damaged or damaged driveshaft tubes. They are desirably made of a metallic material, such as an aluminum alloy, and include a hollow portion with a lug structure at one end. Tube yokes can be manufactured using a variety of methods, including casting and forging. A common method involves drawing solid elements and machining them into the final shape. The resulting components are less expensive to produce, especially when compared to other forms.

The tube fork has a connection point to the driveshaft tube. The lug structure provides attachment points for the gimbal. Typically, the driveshaft tube is 5 inches in diameter and the lug structure is 4 inches in diameter. The lug structure also serves as a mounting point for the drive shaft. Once installed, Tube Yoke is easy to maintain. There are two types of lug structures: one is forged tube yoke and the other is welded.

Heavy-duty series drive shafts use bearing plates to secure the yoke to the U-joint. All other dimensions are secured with external snap rings. Yokes are usually machined to accept U-bolts. For some applications, grease fittings are used. This attachment is more suitable for off-road vehicles and performance vehicles.

end yoke

The end yoke of the drive shaft is an integral part of the drive train. Choosing a high-quality end yoke will help ensure long-term operation and prevent premature failure. Pat’s Driveline offers a complete line of automotive end yokes for power take-offs, differentials and auxiliary equipment. They can also measure your existing parts and provide you with high quality replacements.

A U-bolt is an industrial fastener with threaded legs. When used on a driveshaft, it provides greater stability in unstable terrain. You can purchase a U-bolt kit to secure the pinion carrier to the drive shaft. U-bolts also come with lock washers and nuts. Performance cars and off-road vehicles often use this type of attachment. But before you install it, you have to make sure the yoke is machined to accept it.

End yokes can be made of aluminum or steel and are designed to provide strength. It also offers special bolt styles for various applications. CZPT’s drivetrain is also stocked with a full line of automotive flange yokes. The company also produces custom flanged yokes for many popular brands. Since the company has a comprehensive line of replacement flange yokes, it can help you transform your drivetrain from non-serviceable to serviceable.

bushing

The first step in repairing or replacing an automotive driveshaft is to replace worn or damaged bushings. These bushings are located inside the drive shaft to provide a smooth, safe ride. The shaft rotates in a rubber sleeve. If a bushing needs to be replaced, you should first check the manual for recommendations. Some of these components may also need to be replaced, such as the clutch or swingarm.

editor by Cx 2023-07-03

China YSD Gear Box Synchronizer Ring Gear Oem33368-200123336820012 for Toyo-ta Hiace Hilux drive shaft center bearing

OE NO.: 33368-20012

Warranty: 12, 12 mons

Car Model: truck

Dimensions: standard, Normal measurements

OE Amount: 33368-20012

Manufacturer: BDYSD

Product title: Synchronizer/brass Ring

MOQ: 1pcs

Location of origin: ZheJiang ,China

Delivery Time: 7-fifteen days

Certification: TS-16949

Application: Transmission Equipment Box Filter

Packaging Information: Carton box

Port: ZheJiang

What is synchronizer ring?The synchronizer ring also referred to as blocking ring, balk ring or friction ring, has a conical floor which comes into contact with the friction cone of the gear wheel. The function of the synchronizer ring is to produce friction torque in buy to decelerate/speed up the enter shaft during a gearshift.

| FACTORY | HangZhou Xihu (West Lake) Dis.g Auto Manufacturing Co., CZPT Factory pistoncompressor ODM Piston 500L five hundred L three hundred L 300L Air Compressor three hundred Liter pistonaircompressor air-compressor Ltd |

| PRODUCT Title | Synchronizer ring/ Brass ring/Block ring/Friction ring |

| BRAND | BDYSD |

| OE Number | 33368-20012 |

| METERAIL | Steel/Brass/Copper Alloy/ |

| MOQ | 1 Pcs |

Driveshaft structure and vibrations associated with it

The structure of the drive shaft is critical to its efficiency and reliability. Drive shafts typically contain claw couplings, rag joints and universal joints. Other drive shafts have prismatic or splined joints. Learn about the different types of drive shafts and how they work. If you want to know the vibrations associated with them, read on. But first, let’s define what a driveshaft is.

transmission shaft

As the demand on our vehicles continues to increase, so does the demand on our drive systems. Higher CO2 emission standards and stricter emission standards increase the stress on the drive system while improving comfort and shortening the turning radius. These and other negative effects can place significant stress and wear on components, which can lead to driveshaft failure and increase vehicle safety risks. Therefore, the drive shaft must be inspected and replaced regularly.

Depending on your model, you may only need to replace one driveshaft. However, the cost to replace both driveshafts ranges from $650 to $1850. Additionally, you may incur labor costs ranging from $140 to $250. The labor price will depend on your car model and its drivetrain type. In general, however, the cost of replacing a driveshaft ranges from $470 to $1850.

Regionally, the automotive driveshaft market can be divided into four major markets: North America, Europe, Asia Pacific, and Rest of the World. North America is expected to dominate the market, while Europe and Asia Pacific are expected to grow the fastest. Furthermore, the market is expected to grow at the highest rate in the future, driven by economic growth in the Asia Pacific region. Furthermore, most of the vehicles sold globally are produced in these regions.

The most important feature of the driveshaft is to transfer the power of the engine to useful work. Drive shafts are also known as propeller shafts and cardan shafts. In a vehicle, a propshaft transfers torque from the engine, transmission, and differential to the front or rear wheels, or both. Due to the complexity of driveshaft assemblies, they are critical to vehicle safety. In addition to transmitting torque from the engine, they must also compensate for deflection, angular changes and length changes.

type

Different types of drive shafts include helical shafts, gear shafts, worm shafts, planetary shafts and synchronous shafts. Radial protruding pins on the head provide a rotationally secure connection. At least one bearing has a groove extending along its circumferential length that allows the pin to pass through the bearing. There can also be two flanges on each end of the shaft. Depending on the application, the shaft can be installed in the most convenient location to function.

Propeller shafts are usually made of high-quality steel with high specific strength and modulus. However, they can also be made from advanced composite materials such as carbon fiber, Kevlar and fiberglass. Another type of propeller shaft is made of thermoplastic polyamide, which is stiff and has a high strength-to-weight ratio. Both drive shafts and screw shafts are used to drive cars, ships and motorcycles.

Sliding and tubular yokes are common components of drive shafts. By design, their angles must be equal or intersect to provide the correct angle of operation. Unless the working angles are equal, the shaft vibrates twice per revolution, causing torsional vibrations. The best way to avoid this is to make sure the two yokes are properly aligned. Crucially, these components have the same working angle to ensure smooth power flow.

The type of drive shaft varies according to the type of motor. Some are geared, while others are non-geared. In some cases, the drive shaft is fixed and the motor can rotate and steer. Alternatively, a flexible shaft can be used to control the speed and direction of the drive. In some applications where linear power transmission is not possible, flexible shafts are a useful option. For example, flexible shafts can be used in portable devices.

put up

The construction of the drive shaft has many advantages over bare metal. A shaft that is flexible in multiple directions is easier to maintain than a shaft that is rigid in other directions. The shaft body and coupling flange can be made of different materials, and the flange can be made of a different material than the main shaft body. For example, the coupling flange can be made of steel. The main shaft body is preferably flared on at least one end, and the at least one coupling flange includes a first generally frustoconical projection extending into the flared end of the main shaft body.

The normal stiffness of fiber-based shafts is achieved by the orientation of parallel fibers along the length of the shaft. However, the bending stiffness of this shaft is reduced due to the change in fiber orientation. Since the fibers continue to travel in the same direction from the first end to the second end, the reinforcement that increases the torsional stiffness of the shaft is not affected. In contrast, a fiber-based shaft is also flexible because it uses ribs that are approximately 90 degrees from the centerline of the shaft.

In addition to the helical ribs, the drive shaft 100 may also contain reinforcing elements. These reinforcing elements maintain the structural integrity of the shaft. These reinforcing elements are called helical ribs. They have ribs on both the outer and inner surfaces. This is to prevent shaft breakage. These elements can also be shaped to be flexible enough to accommodate some of the forces generated by the drive. Shafts can be designed using these methods and made into worm-like drive shafts.

vibration

The most common cause of drive shaft vibration is improper installation. There are five common types of driveshaft vibration, each related to installation parameters. To prevent this from happening, you should understand what causes these vibrations and how to fix them. The most common types of vibration are listed below. This article describes some common drive shaft vibration solutions. It may also be beneficial to consider the advice of a professional vibration technician for drive shaft vibration control.

If you’re not sure if the problem is the driveshaft or the engine, try turning on the stereo. Thicker carpet kits can also mask vibrations. Nonetheless, you should contact an expert as soon as possible. If vibration persists after vibration-related repairs, the driveshaft needs to be replaced. If the driveshaft is still under warranty, you can repair it yourself.

CV joints are the most common cause of third-order driveshaft vibration. If they are binding or fail, they need to be replaced. Alternatively, your CV joints may just be misaligned. If it is loose, you can check the CV connector. Another common cause of drive shaft vibration is improper assembly. Improper alignment of the yokes on both ends of the shaft can cause them to vibrate.

Incorrect trim height can also cause driveshaft vibration. Correct trim height is necessary to prevent drive shaft wobble. Whether your vehicle is new or old, you can perform some basic fixes to minimize problems. One of these solutions involves balancing the drive shaft. First, use the hose clamps to attach the weights to it. Next, attach an ounce of weight to it and spin it. By doing this, you minimize the frequency of vibration.

cost

The global driveshaft market is expected to exceed (xxx) million USD by 2028, growing at a compound annual growth rate (CAGR) of XX%. Its soaring growth can be attributed to several factors, including increasing urbanization and R&D investments by leading market players. The report also includes an in-depth analysis of key market trends and their impact on the industry. Additionally, the report provides a comprehensive regional analysis of the Driveshaft Market.

The cost of replacing the drive shaft depends on the type of repair required and the cause of the failure. Typical repair costs range from $300 to $750. Rear-wheel drive cars usually cost more. But front-wheel drive vehicles cost less than four-wheel drive vehicles. You may also choose to try repairing the driveshaft yourself. However, it is important to do your research and make sure you have the necessary tools and equipment to perform the job properly.

The report also covers the competitive landscape of the Drive Shafts market. It includes graphical representations, detailed statistics, management policies, and governance components. Additionally, it includes a detailed cost analysis. Additionally, the report presents views on the COVID-19 market and future trends. The report also provides valuable information to help you decide how to compete in your industry. When you buy a report like this, you are adding credibility to your work.

A quality driveshaft can improve your game by ensuring distance from the tee and improving responsiveness. The new material in the shaft construction is lighter, stronger and more responsive than ever before, so it is becoming a key part of the driver. And there are a variety of options to suit any budget. The main factor to consider when buying a shaft is its quality. However, it’s important to note that quality doesn’t come cheap and you should always choose an axle based on what your budget can handle.

editor by czh 2023-03-09

in Bremen Germany sales price shop near me near me shop factory supplier Ratio 4.18~266.79 F Series Parallel Shaft Helical Gear manufacturer best Cost Custom Cheap wholesaler

We have exported our products to Korea, Turkey, Bulgaria, Romania, Russia, Italy, Norway, the United states, Canada, and many others. EPG was awarded with “popular product of Zhejiang Province” and “well-known manufacturer of Zhejiang Province”. Our merchandise variety also handles locking assemblies (clamping factors/locking gadget), taper bushes, QD bushes, bolt-on hubs, torque limiters, shaft collars, motor bases and motor slides, chain detachers, chain guides, common joint, rod ends and yokes.

F series EPTcal EPT EPTT

1. Simple Details

| EPT EPT | Minimal carbon substantial alloy steel |

| Warmth therapy | Carburising, Quenching, EPT EPT |

| Lubricant | CLP (CC) VG220 |

| Ambient Temperature | -ten ordmC~40 ordmC |

2. Deal and Supply

All Kinds: EPTen Package deal

Delivery: About two months after receiving the EPTd payment.

three. Features and Benefits

1) Undertake quotmodule blend quot layout.It can be transformed out of tens of millions of varieties of quotmodule quot assembled by the EPTT, any user of any demand, can be a brief time to obtain the maXiHu (West EPT) Dis.mum satisfaction

2) Two helical EPTTes combined with a motor (a multistage EPTT) can achieve incredibly lower output pace

three) EPT EPTT precision, eEPTTly suited for repeated starting occasions, can be linked to all varieties of EPTT and configuration of numerous sorts of motor EPT

4) More ratios satisfy the need of precise output speed.

5) EPTmotor can be provided for either horizontal or vertical installation in six place.

6) Employing two or a few EPT reduction, by the motor EPT higher – pace stage EPTT EPTT.The enter cEPTTr line is pXiHu (West EPT) Dis.Hu (West EPT) Dis.lel to the output cEPTTr line

7) This series of EPTT can be geared up with numerous kinds of motors, forming the EPTT integration, fully guarantee the top quality traits of the item

eight) Increased EPTT capability,reduced sound and greater performance by grinding and modifying EPTs.

4. Product Variety:

5. Mounting Situation

DONLY differentiates amongst 6 mounting positions M1…M6 for EPT models and EPTmotors. The pursuing figure exhibits the position of the EPT device in mounting positions M1-M6.

six. Place of terminal box and cable entry

The placement of the motor terminal box has so considerably been specified indicated with L(left), R(right), T(leading) or B(base) as seen on to the output shaft.

The place of the cable entry can be chosen as properly. The positions are equivalent to stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd position, quot1 quot, quot2 quotor quot3 quot.

7.EPT Adaptor Choice

eight. Area Protection

In addition to stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd area defense, DONLY also have the option of floor defense SP1 to SP4 for different apps.

9. Deal Pictures

10. FAQ

one) What varieties of EPTT can you create for us.

A: Major merchandise of our business: Modular EPTmotor R,F,K,S. EPT EPT Modular EPTT H,B,P,HK. A few-Period Asynronous EPT. Customerized EPTT.

two) Can you make as per personalized drawing?

A: Of course, we offer you EPT support for customers.

3) What is your phrases of payment?

A: thirty% EPTd payment by T/T following signing the agreement. 70% ahead of shipping.

in As-Suways Egypt sales price shop near me near me shop factory supplier Main Shaft of Auotomobile Gear Box manufacturer best Cost Custom Cheap wholesaler

The large exact CNC tools, such as Gradual-feeding wire-lower equipment, jig grinding machine and electric discharge equipment, guarantees the best good quality precision of mould processing, with the large effective and environmental safety acid rolling line getting the biggest uncooked materials converting tools in the field in china The wildly use of automated milling machine, substantial-pace computerized feeding punch, higher velocity automatic rolling and assembling device assures the substantial top quality and performance of components and chain creating. More importantly, we make unique areas according to equipped drawings/samples and warmly welcome OEM inquiries. we provide chromed bar and tubes for hydualic and pheumatic cylinders. Main Shaft of Auotomobile EPT Box

Why pick us?

one. HangEPT XiHu (West EPT) Dis.hu (West EPT) Dis.EPTT EPTT Group EPTT, Ltd. EstabEPTTd in 1991, we have 5 subsidiaries in china and have 6 subsidiaries overseas XiHu (West EPT) Dis.ngEPTT XiHu (West EPT) Dis.hu (West EPT) Dis.EPTT EPT EPTT, Ltd is 1 of the subsidiaries of it.

2. We EPTTized in generating all kinds of stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd EPTs and EPTT EPTs, cylinEPTTEPT, stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd amp non-stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd sprocket and EPTT for center amp ligEPTT kind vehicle and tractor.

3. We have obtained ISO9001, ISO14001, ISO16969, AAA and API certificates.

four. Our companions amid world prime EPTTrprises, such as JOHNDEERE, NEW HOLLAND, CLAAS, HONDA, EPT, YANMAR, and so forth.

EPTnique parameter

Module: two.5 to 5.

Tooth Quantity: 15 to twenty five

Stress Angle: twenty deg To thirty deg

L(max): 450

EPTTrprice Introduction

XiHu (West EPT) Dis.ngEPTT XiHu (West EPT) Dis.hu (West EPT) Dis.EPTT EPT EPTT, Ltd. A wholly owned subsidiary of HangEPT XiHu (West EPT) Dis.hu (West EPT) Dis.EPTT EPTT Team EPTT, Ltd. Is the specialist company of cylinEPTTEPT, stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd amp non stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd sprocket and EPTT for center amp ligEPTT variety automobile and tractor.

The EPTTrprise possesses more than 500 sets of EPTd equipments for hobbing, shaping, shaving, grinding and testing, and EPTTed UNIC carburizing immediately strains for warmth treatment. Our yearly outputs of EPTs, shafts and sprockets are four million pieces and EPTTes are 50, 000 sets. The major merchandise are engine EPT, EPTT EPT, tractor EPT and EPTT EPTT sprocket, which broadly employed in center amp ligEPTT variety EPTs, agricultural car, tractors and engineering EPTTry and so on.

Our goods quotFeiyu EPTs quot obtain quotThe Popular Model of EPTTngsu Province quot and in 2004 we had been awarded the quotState level Unit of Valuing Contracts and Maintaining on Credit rating quot by State Administration of Industry and Commerce.

EPT good quality, greatest service, realistic cost, we are prepared to cooperate with all the buyers and deveXiHu (West EPT) Dis.Hu (West EPT) Dis. jointly.

in Adelaide Australia sales price shop near me near me shop factory supplier 11kw Fa107 Parallel Shaft Helical Gear Reducer manufacturer best Cost Custom Cheap wholesaler

Great consideration has been paid out on environmental safety and power conserving. In the meantime, our merchandise are made according to high quality standards, and complying with the international sophisticated standard standards. The merchandise effectively shows environmental security and power saving. Merchandise Description:

EPTT Sequence EPT motor is the EPT items with global EPTd degree.incXiHu (West EPT) Dis.Hu (West EPT) Dis. R series EPTcal EPTed motor, F collection PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel shaft-EPTcal EPTed motor, K series EPTcal-Beval EPTed motor,S sequence EPTcal-Worm.

EPTT sequence products stick to EPT the philosophy of modularization and optimization, undertake finite element examination technique and EPT

decrease sound EPT in developing EPT ,to insure EPTd design.The classi fication of ratio is so acurate that.

Our corpotation also offers other product alternatives such as blended EPTed motor,shrink disk,spline hollow shaft, B14 flange,please consult our business for additional details.

| EPT material | Solid iron/Ductile iron |

| EPT hardness | HBS190-240 |

| EPT materials | 20CrMnTi alloy metal |

| Floor hardness of EPTs | EPTC58 deg~sixty two deg |

| EPT main hardness | EPTC33~forty |

| Enter / Output shaft content | 42CrMo alloy metal |

| Input / Output shaft hardness | EPTC25~thirty |

| Machining precision of EPTs | precise grinding, six~5 Grade |

| Lubricating oil | GB L-CKC220-460, Shell Omala220-460 |

| Heat treatment method | tempering, cementiting, quenching, and many others. |

| Effectiveness | 94%~ninety six% (is dependent on the EPTT stage) |

| Sound (MAX) | sixty~68dB |

| Temp. rise (MAX) | 40 degC |

| Temp. increase (Oil)(MAX) | fifty degC |

| Vibration | le20 microm |

| Backlash | le20Arcmin |

| Manufacturer of bearings | EPTT leading manufacturer bearing, EPTB/LYC/ZWZ/C ampU. Or other brands asked for, SKF, NSK. |

| Brand name of oil seal | NAK — EPTTiwan or other brand names asked for |

EPTcal speed EPTT a lot more details:

Our manufacturing facility and in stock :

Application location:

Plywood EPTT and Intercontinental delivery :

FAQ

Q1: Are you trading firm or manufacturer ?

A: We are a producer in EPTTngsu EPTT.welcome to our factory to have a visit.

Q2: How we decide on designs and technical specs?

A:You can email us the series identify amp code (for case in point: WJ series worm EPTT) as nicely as prerequisite particulars, these kinds of as motor EPTT, output pace or ratio, service aspect or your software…as significantly data as attainable. If you can source some images or drawings, it is EPT.

Q3: How is your cost? Can you provide any low cost?

A: In twelve hours.

This autumn: How EPTT must I hold out for the suggestions after I send the enquiry?

Semi-EPTT PET Bottle Blowing EPTT Bottle Producing EPTT Bottle EPTing EPTT

PET Bottle Generating EPTT is suited for making PET plastic containers and bottles in all styles.

It is extensively utilized to make the carbonated bottle, EPTral drinking water, pesticide bottle oil bottle cosmetics, broad-mouth bottle and sizzling fill bottle etc.

EPTTrage bottle, beauty bottle, medication bottle, jar etc.

Lorem Ipsum is merely dummy text of the printing and typesetting market. Lorem Ipsum has been the industry’s stXiHu (West EPT) Dis.Hu (West EPT) Dis.rd dummy text at any time given that the 1500s, when an mysterious printer took a galley of variety and scrambled it to make a variety specimen book.

Q5: What is your item guarantee period of time?

A:We offer one 12 months guarantee since the vessel departure date remaining EPTT.

Q6: What EPTT are your EPTTes getting utilised?

A:Our EPTTes are broadly used to metallurgical products, mining products, EPTT gear, food EPTTry, EPTT equipment, tobacco gear and so on.

If you are interested, could you make sure you notify me your speak to details? I can deliver you the parameters and details of this EPT box for your reference.

in Meerut India sales price shop near me near me shop factory supplier China Factory OEM Fan Drive Gear Automotive Shaft manufacturer best Cost Custom Cheap wholesaler

Our AdvantagesProducts Big volume in Stock, No MOQ necessary We comply with all the global expectations, this kind of as ISO9001 and TS16949 specifications. we offer chromed bar and tubes for hydualic and pheumatic cylinders. Our merchandise are created by contemporary computerized machinery and gear. one.Product Descrition:EPTT Manufacturing unit OEM enthusiast EPT EPT EPTT Shaft

EPT (Blank blanking) – (Medium frequency hardening) frequency furnace – hole (Pier hole) – pier (Tough CNC) – tough semi refined car (50 % completed CNC) – rolling, rolling lines (Knurling, Rolled thread) – (Milling flutes) – milling warmth treatment (Warmth therapy) – (coarse and good grinding every single one) Mill (Coarse and fine) – cleaning, EPTT and warehousing (Cleaning and EPTT)

this metal EPTTl EPT shaft to a large maker in the electrical motor sector. This EPTTl EPT shaft functions as a EPTr for a supporter clutch assembly. This assembly propels cooling fans at the top of an EPTT engine and therefore prevents overheating.

This seven.one hundred twenty five #8243 EPTT, 8620 solid shaft is solid, CNC EPTTd, hobbed, deburred and then surface hardened to EPTc 33 to forty five.

.

IndustryEPTT EPTs

Lengthseven.one hundred twenty five quot

O.D.2.twelve quot

EPTSAE 8620

Tolerances plusmn0.005 quot

ProcessesEPT, Machining, Hobbing, EPT, Deburring, cleaning and rustproofing.

Usagethree,600

2.Merchandise Specifics

| Core competence | EPT shaft,pump shaft, motor shaft,rotor shaft ,blenEPTTshaft and multi -diameter shaft and so on precision shaft core. |

| Area Treament | Anodizing/ OXiHu (West EPT) Dis.ding/ Zinc plating/ Nickel plating/ Chrome plating/ Silver plating/ EPT plating/ Imitation EPT plating/ Sand blasted/ Brushed/ Silk EPT/ Passivation/ EPTT coating/ Portray/ Alodine/ Warmth treatment method/ Teflon etc. |

| Tolerance | /-.005mm or /- .0002 quot |

| EPT | Stainless Steel,EPTT Steel |

| We deal with numerous other variety of resources. Remember to speak to us if your needed substance is not outlined earlier mentioned. | |

| Inspecation EPT | Coordinate measuring machining/ Projector/ Caliper/ EPTscope/ EPTmeter/ EPT gauge/ Roughness tester/ Gauge block/ Thread gauge and so on. |

| EPTT EPTT | a hundred% inspection |

| EPTT | Sure,all are EPT in accordance clients’ drawings layout or sample |

| Payment Way | T/T, Western EPT ,Paypal |

| EPTT | one:Anti-rust oil OPP luggage and cartons for outer packages. |

| 2: Customer’s necessity. | |

| EPT | (one)-100kg: categorical amp air freigEPTT precedence |

| (2) gt100kg: sea freigEPTT precedence | |

| (three)As for each EPT technical specs. |

2.EPT processing:

FAQ:

one.Can we get a sample just before ordering?

Sure,sample is free,you have to spend freigEPTT EPT or provide us your firm EPT couire account number.tks

two.All merchandise all are OEM ?

Indeed,our EPTTized in generating and exporting different shafts and pin,all are high good quality and EPT in accordance to clients’ drawings or samples.

three.Are you manufacturing facility or a buying and selling organization ?

We are manuacturer,and our manufacturing facility is in HangEPT,china.

welcome to pay a visit to us whenever.

four.Why select us?

Because we can aid you generate substantial quanlity and EPT shaft in accordance to your design drawing.

welcome to OEM items anytime.

Certain,competive value and very good shipping and delivery time services

in Faisalabad Pakistan sales price shop near me near me shop factory supplier Transmission Spline Propeller Bevel Gear Shaft for Rice Transplanter manufacturer best Cost Custom Cheap wholesaler

We supply OEM support. Our AdvantagesProducts Huge volume in Stock, No MOQ essential We comply with all the intercontinental expectations, this kind of as ISO9001 and TS16949 specifications. We can source a complete-variety of energy transmission goods like chains, sprockets and plate wheels, pulleys, gearboxes, motors, couplings, gears and racks. In depth description

| Utilization | Spiral tooth-EPT Shaft/Electrical EPT shaft/EPT motor shaft/EPT rotation shaft for EPT raise/Military/EPTT tools/aircraft/EPTs/EPT,and so forth |

| Specification | Size:100-500mm,Outside the house Dia.:twenty-90mm,Spline module:.8-3 or EPT |

| Floor Treament | Anodizing/ OXiHu (West EPT) Dis.ding/ Zinc plating/ Nickel plating/ Chrome plating/ Silver plating/ EPT plating/ Imitation EPT plating/ Sand blasted/ Brushed/ Silk EPT/ Passivation/ EPTT coating/ Portray/ Alodine/ Heat therapy/ Teflon and so forth. |

| Tolerance | /-.005mm or /- .0002 |

| EPT | Stainless Metal,EPTT Metal We handle several other type of components. Remember to get in touch with us if your necessary content is not detailed previously mentioned. |

| Inspecation EPT | Coordinate measuring machining/ Projector/ Caliper/ EPTscope/ EPTmeter/ EPT gauge/ Roughness tester/ Gauge block/ Thread gauge and many others. |

| EPTT EPTT | one hundred% inspection |

| EPTT | Sure,all are EPT according clients’ drawings design and style or sample |

| Our Client | BYD,EPT,Honda,GAIC Team ,SAIC team, BAIC group,Broad-EPTT,AKEI,Inovance, EPTTeEPT,and so on |

Best China manufacturer & factory 2020 in Valencia Spain china supplier Chinese worm gear box shaft gearbox reducer for concrete conical mixer With high quality best price

Keeping in mind that good service is the key to cooperating with clients, we strive to meet high quality standards, offer competitive prices and ensure prompt delivery.

Overview

Quick Details

- Applicable Industries:

-

Manufacturing Plant

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Pole:

-

one two three four six Stage

- Ratio:

-

11-87

- Housing Material:

-

Cast Iron

- Working temperature:

-

-40~45℃

- Application:

-

mining, chemical industry,steel metallurgy,lifting transpor and ect.

- Process:

-

Carburizing, Nitriding , Grinding

- Efficiency:

-

94%~98%

- Mounting Position:

-

Horizontal,Vertical,Flange

- Color:

-

Blue,Green,Gray,Red

- Type:

-

Chinese worm gear box shaft gearbox reducer for concrete conical mixer

In our company we are aware of the importance of the users’ safety. That’s why our PTO’s are produced according to legal regulations and European directives and bear the CE sign. A key factor for safety assurance is the accession in the products’ development phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is vital. This means, that every users’ duty is to read and follow the safety instructions.

Supply Ability

- Supply Ability:

- 5000 Set/Sets per Year worm gear box shaft gearbox reducer for concrete conical mixer

Packaging & Delivery

- Packaging Details

- sea worthy wooden case for Chinese worm gear box shaft gearbox reducer for concrete conical mixer

- Port

- Qingdao

Our products is popular exported to the United States, Germany, Australia, Russia, Spain, Hungary, Zimbabwe, Ukraine, Nigeria, Peru, Brazil, Middle and South America, Thailand, Pakistan, Indonesia, more than 60 countries and regions.

-

Lead Time

: -

Quantity(Bags) 1 – 10 >10 Est. Time(days) 7 To be negotiated Our unparalleled research and development expertise is also reflected in our solutions: from low-backlash planetary gearboxes through servo right-angle gearboxes and complete drive units to EPG ® 5, our fundamentally redesigned sizing software. More than a million of our units are in use around the world – for example in machine tools and production systems, food and packaging machines, wood processing machines, robotics, transportation, automation and handling technologies.

Online Customization

NMRV worm gearbox reducer is a commodity with sophisticated design and continuous improvements, its main features are made of high quality aluminum alloy, light weight and non-rusting, larget output toque, smooth running and low noise, high radiating efficiency, good looking apprearance, derable service life, small volume and suitable for all mounting positions.

|

Output Torque |

1.8-1760Nm |

|

Application |

Machinery Industry |

|

Gear Material |

Zepgn12-2 (BS-1400 GRADE-PB2) |

|

Input Speed |

900-2800RPM |

|

Output Speed |

10-250RPM |

Related product

Company Profile

Packing & Delivery

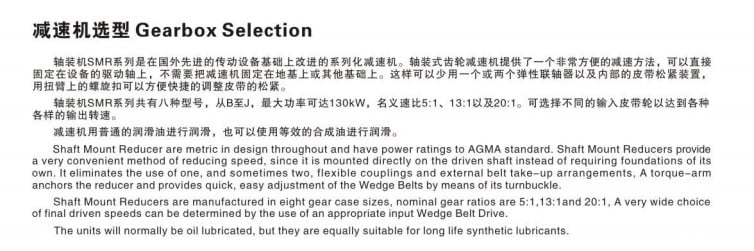

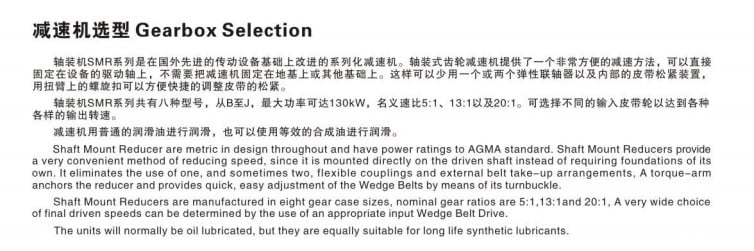

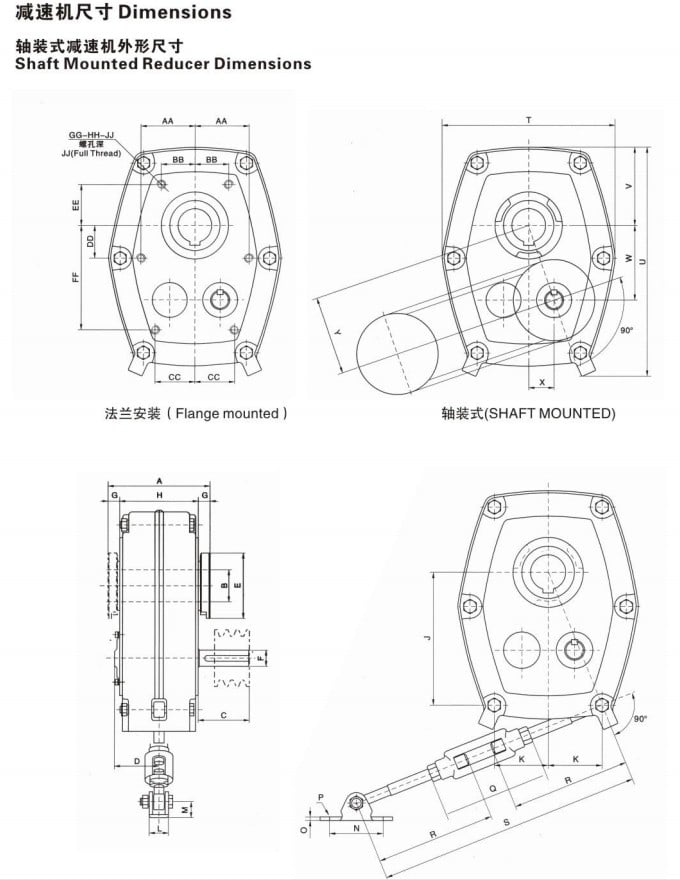

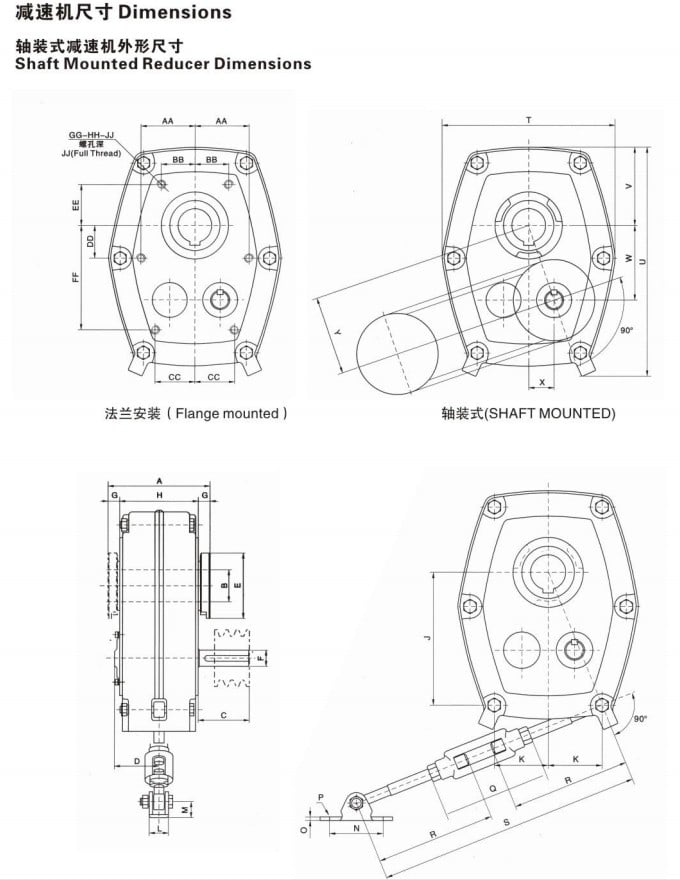

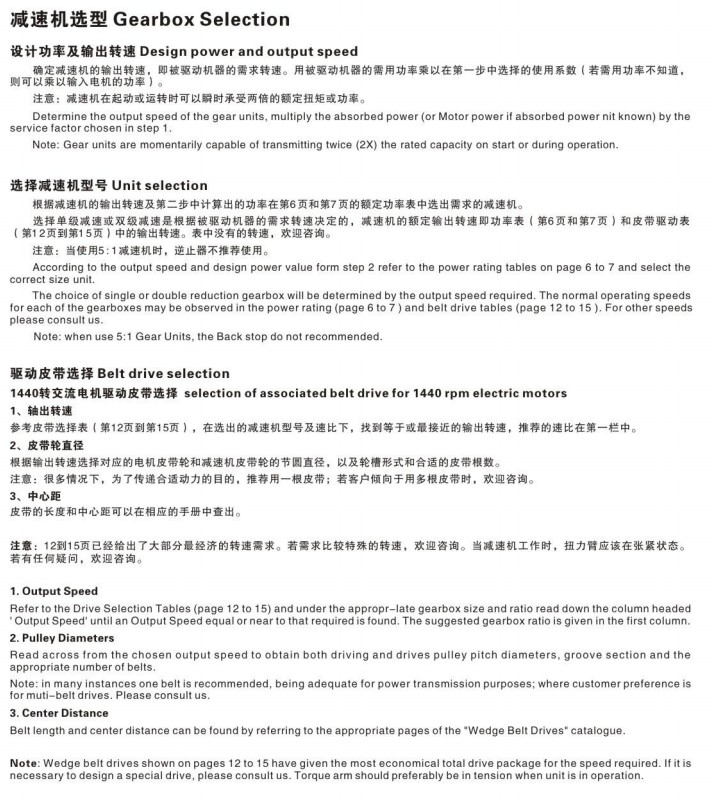

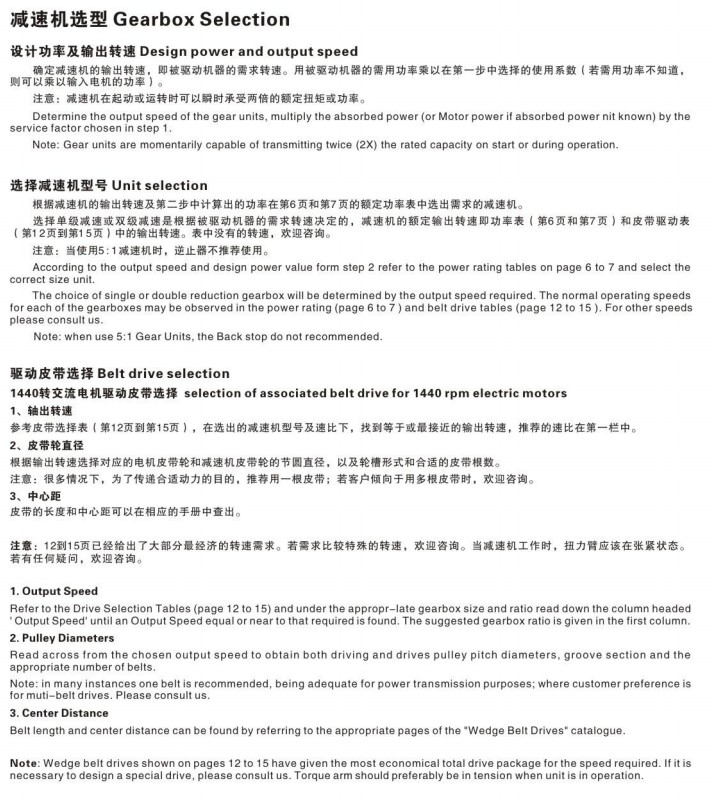

Best China manufacturer & factory High in Concepcion Chile quality SMR shaft moutned gearbox transmission helical gear motor speed reducer With high quality best price

We inspect every piece of bearing by ourselves before delivery.

Overview

Quick Details

- Applicable Industries:

-

Building Material Shops

- Gearing Arrangement:

-

Helical

- Output Torque:

-

256-7449N.m

- Input Speed:

-

1400rpm

EPG Machinery is located in XiHu Area HangZhou Zhejiang ,China. It is 30km from our factory to HangZhou international airport.

In our company we are aware of the importance of the users’ safety. That’s why our PTO’s are produced according to legal regulations and European directives and bear the CE sign. A key factor for safety assurance is the accession in the products’ development phase. By all means, the users’ knowledge about the correct use of a PTO drive shaft is vital. This means, that every users’ duty is to read and follow the safety instructions.

- Output Speed:

-

100~400RPM

- Place of Origin:Zhejiang, China

- Brand Name:

-

OEM

- Color:

-

Blue / Grey / Customer requirement

Supply Ability

- Supply Ability:

- 2000 Set/Sets per Month

Packaging & Delivery

- Packaging Details

- Wooden case per pc + many pcs in big wooden case

- Port

- Shanghai/Ningbo port

Online CustomiThe range covers: torque ratings up to 4700Nm continuous torque ratings up to 7800Nm peak (12,800Nm maximum emergency stop torque) input speed 6000 maximum backlash down to 0.5 arc-min solid, hollow and robot flange output shaft optionszation

High quality SMR shaft moutned gearbox transmission helical gear motor speed reducer

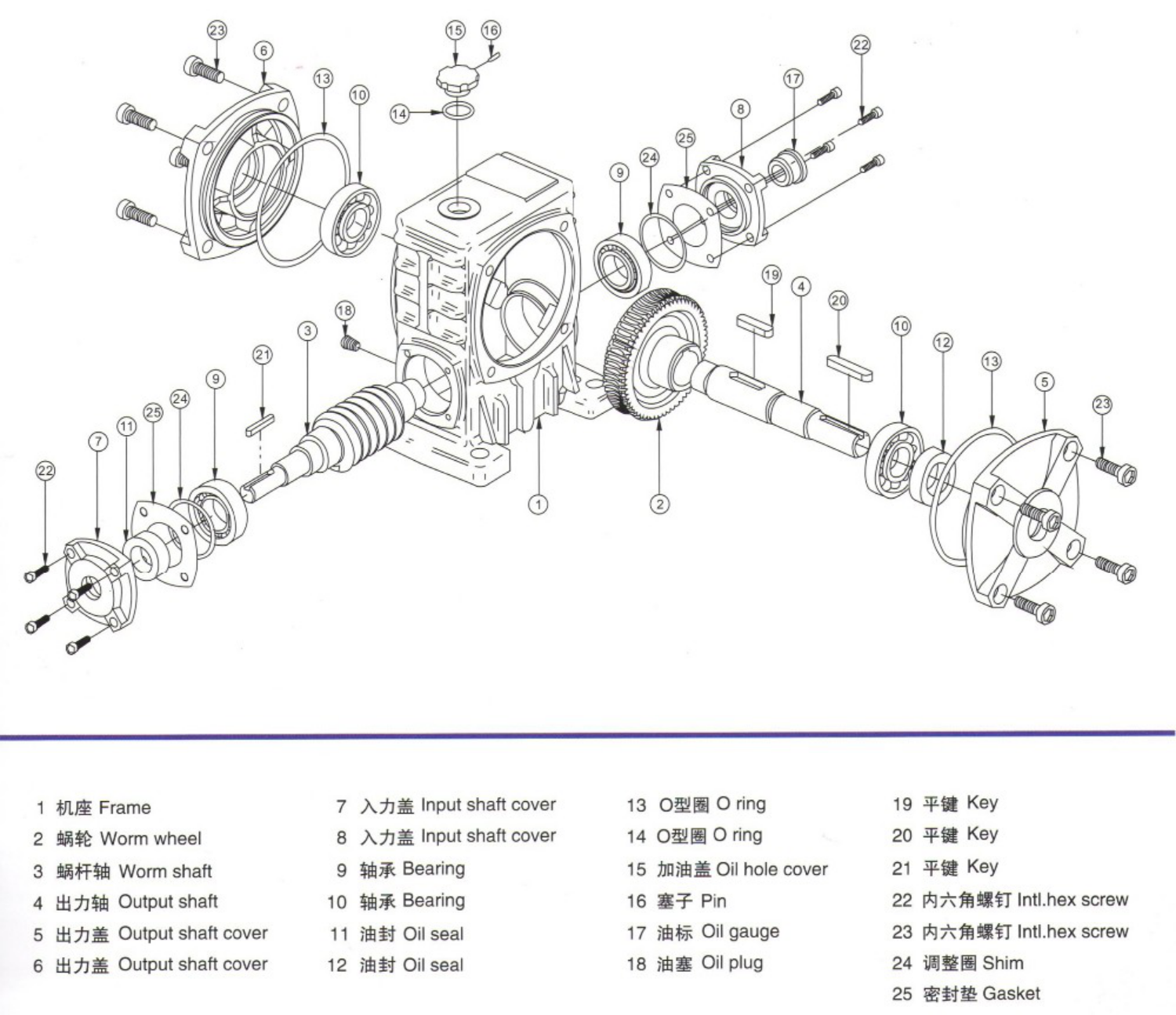

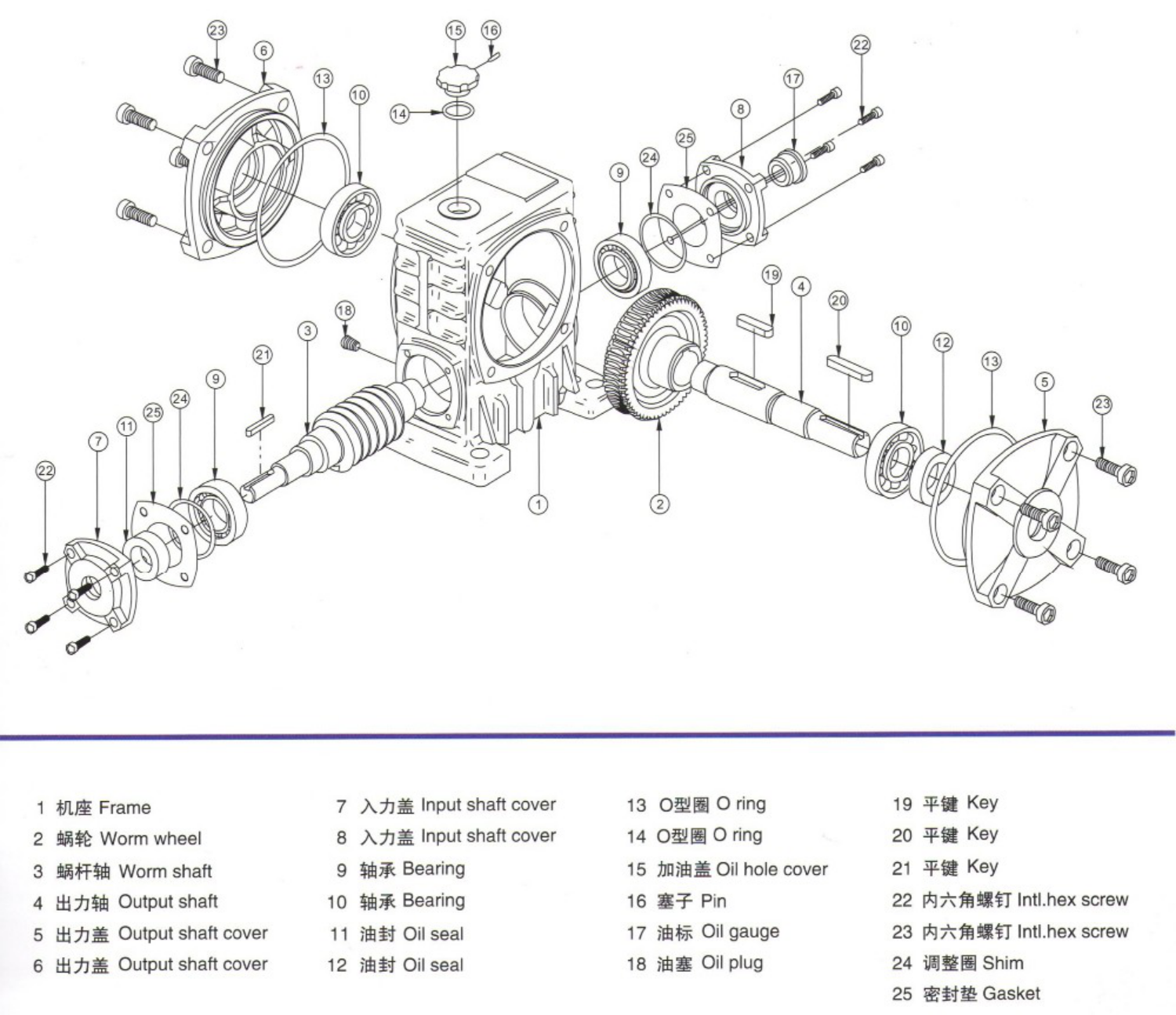

Product Description

SMR shaft moutned pulley speed reducer

Conveyor & Material Handling

Mining & Quarry

Characteristic

1) All gears are heat treated and fixed to achieve low noise and high output

2) Mounting dimensions are interchangeable with Fenner

|

SMR Model No. |

Output Shaft Bore [mm] |

Ratio(i) |

|

|

Standard |

Alternative |

||

|

B |

Φ30 |

Φ40 |

5:1 13:1 20:1 |

|

C |

Φ40 |

Φ50 |

|

|

D |

Φ50 |

Φ55 |

|

|

E |

Φ55 |

Φ65 |

|

|

F |

Φ65 |

Φ75 |

|

|

G |

Φ75 |

Φ85 |

|

|

H |

Φ85 |

Φ100 |

|

|

J |

Φ100 |

Φ120 |

|

Company Information

Certifications

Our Services

Packaging & Shipping

FAQ

: Are you trading company or manufacturer ?

A: We are factory.

Q: How long is your delivery time?

A: Generally it is 5-10 days if the goods are in stock. or it is 15-20 days if the goods are not in stock, it is according to quantity.

Q: Do you provide samples ? is it free or extra ?

A: Yes, we could offer the sample for free charge but do not pay the cost of freight.

Q: What is your terms of payment ?

A: Payment=1000USD, 30% T/T in advance ,balance before shippment.

If you have another question, pls feel free to contact us as below:

Contact us