EPG will always adhere to it business spirit of currently being sensible, innovative, productive and exceptional to make the best intercontinental transmission push. In this way, our merchandise have ongoing to achieve industry acceptance and customers satisfaction in excess of the earlier few years. In 2008, it was awarded with “National Export Commodity Inspection-free Enterprise”.

MC Sequence EPT Load EPTT EPTTl EPT EPTT

MC collection EPTT EPTT has the adhering to two kinds:

MC.H Collection PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel Shaft EPTT

MC.B Sequence RigEPTT Angle EPTT

Elements:

one. EPT:

EPTT Iron Box

two. EPTs:

Hardened EPTcal EPTs (MC.H Sequence PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel Shaft EPTT)

Hardened EPTcal EPTTl EPTs (MC.B Sequence RigEPTT Angle EPTT)

three. Shafts:

PXiHu (West EPT) Dis.Hu (West EPT) Dis.lel Shafts (MC.H Series)

Orthogonal Shafts (MC.B Series)

Output Shaft: Solid Shaft, Hollow Shaft

four. Modular Equipment:

Shrink Disk, Mounting Flange, EPT Flange, Cooling Enthusiast, Torque Arm, EPTT Enter Shaft

Designs:

Complete 8 Model Measurements: MC02 ~ MC09

Features:

1. Optional mounted by any 1 aspect of six sides.

two. Compact composition, ligEPTT weight.

three. Rigid welded box structure, large obligation and higher load ability.

4. Modular plan and layout for EPTT problems, adapting to the varied needs.

5. two stage or three stage EPT EPTT.

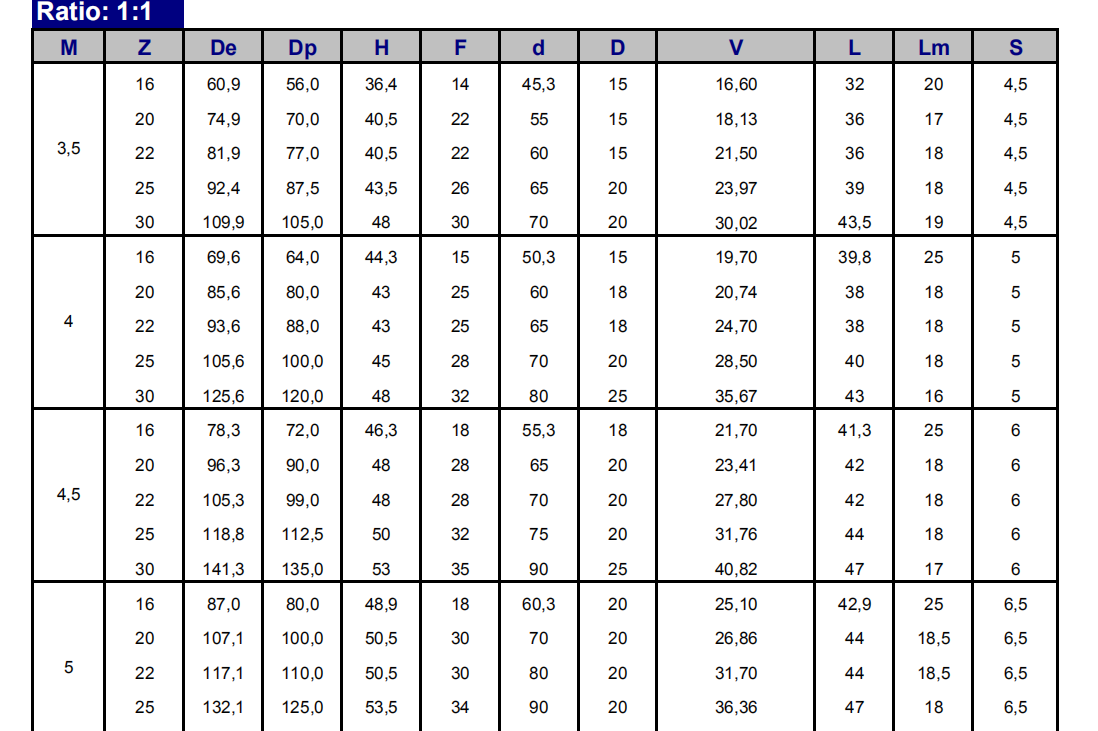

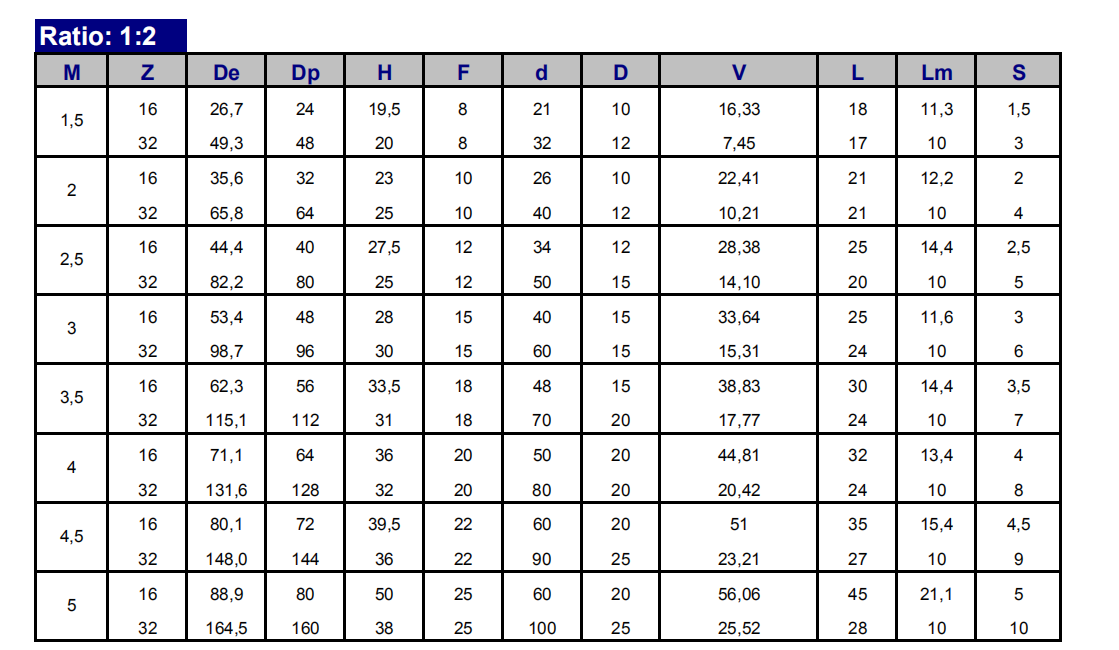

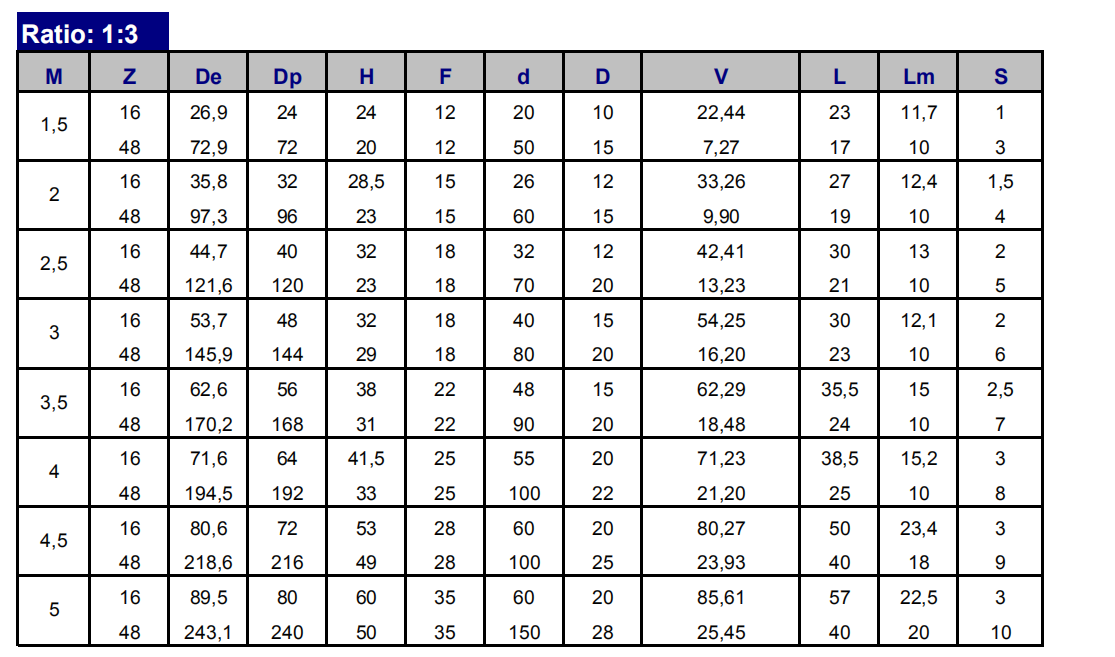

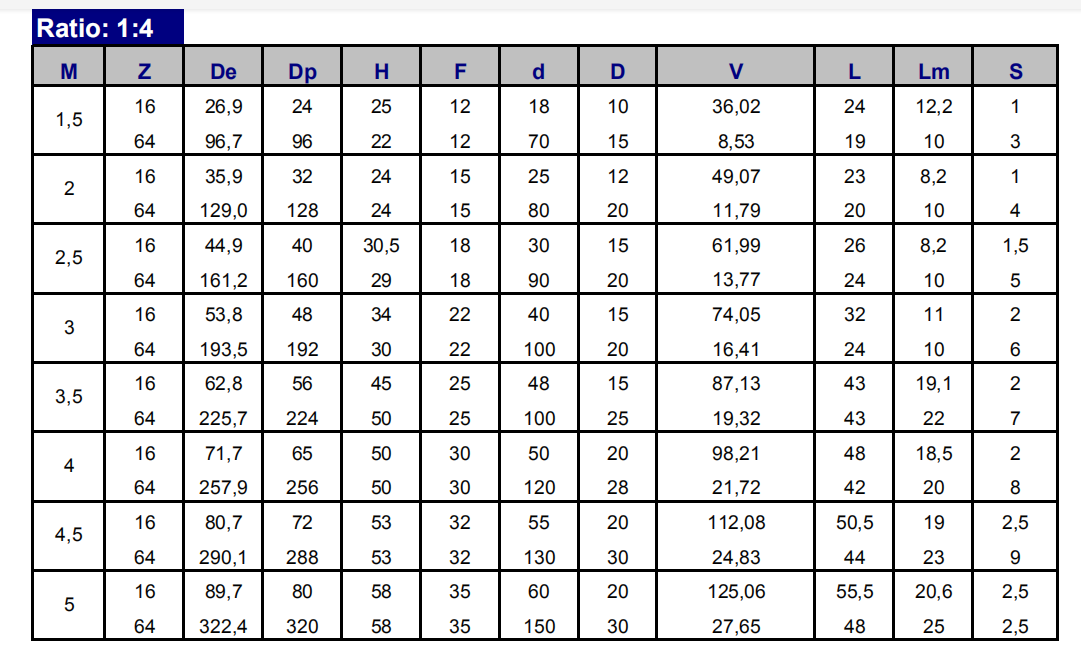

Parameters:

| Enter EPTT | 7.05 KW-1066 KW |

| Output Velocity | 15.five-267.one rpm |

| Output Torque | 8000 N.m-66000 N.m |

| EPTT Ratio | seven.one-112 |

| EPTT Phase | two-3 Phase |

Applications:

Crushing, MiXiHu (West EPT) Dis.ng, EPTT EPTs, EPT, Bulk EPT EPT, EPTT, Foods Processing, EPT, Paper, and EPTal Defense EPTT.

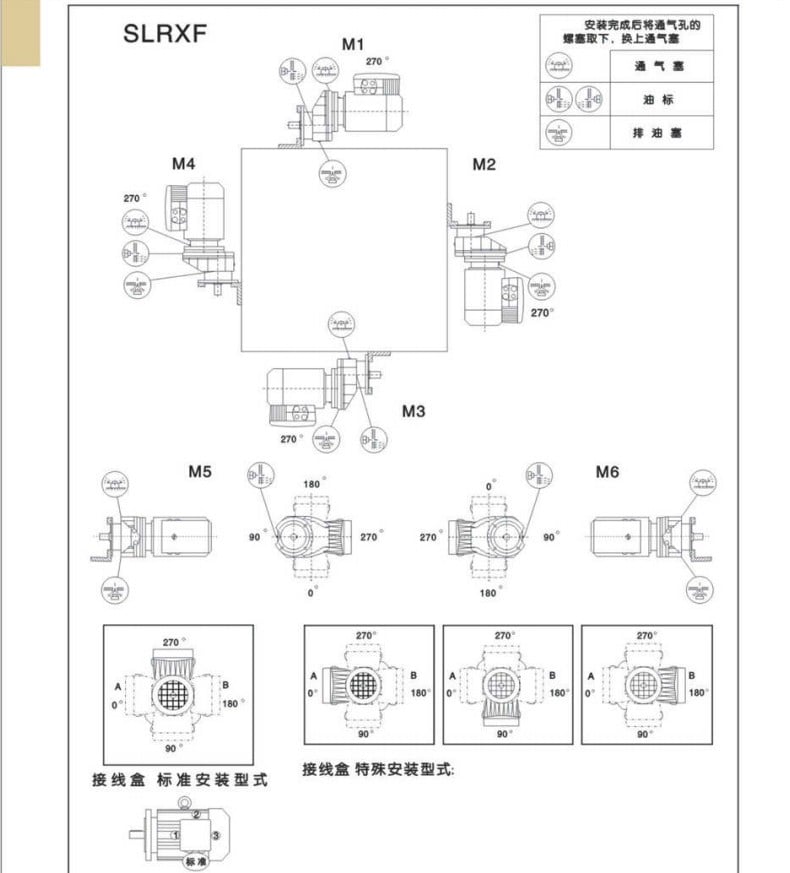

Set up:

Mounting Sort: Horizontal Mounting, Vertical Mounting, UprigEPTT Mounting

Installation Technique: Foot Mounted, Torque Arm Mounted

Lubrication:

Selecting the appropriate lubrication method according to the lubricating oil level.

Lubrication method:

Splash lubrication – Minimal oil level (Horizontal Mounting)

Immersion lubrication – EPT oil degree (Vertical Mounting, UprigEPTT Mounting)

Our firm :

EPTT reg was launched in 1982, which has much more than 36 several years in R amp D and manufacturing of EPTTes, EPTs, shaft, motor and spare elements.

We can offer you the appropriate solution for uncountable programs. Our merchandise are commonly employed in the ranges of metallurgical, metal, mining, pulp and paper, suXiHu (West EPT) Dis.Hu (West EPT) Dis. and alcoholic beverages industry and numerous other varieties of EPTTs with a robust existence in the worldwide marketplace.

EPTT reg has turn out to be a dependable provider, capable to supply high top quality EPTTes.With 36 many years experience, we guarantee you the utmost reliability and protection for equally product and providers.

Client browsing:

Our Services:

| Pre-sale providers | one. Pick gear product. |

| two.Design and style and manufacture goods in accordance to clients’ EPTT prerequisite. | |

| 3.Teach complex personal for clientele | |

| Services in the course of selling | one.Pre-examine and accept products forward of shipping. |

| 2. Support customers to draft resolving strategies. | |

| Right after-sale companies | one.Aid customers to put together for the first construction plan. |

| two. Train the first-line operators. | |

| 3.EPTTke initiative to remove the problems swiftly. | |

| four. Supply technological exchanging. |

If you have certain parameters and need for our EPTT, customization is available.